High Performance Markets for A206 Aluminum Castings

Combat & Tactical Vehicles, Cars, Off-Road Trucks & Jeeps, Military Jets

Lightweight, Tough & Reliable

Mechanical Properties

The mechanical properties and heat treat on the A206 are defined by the SAE Aerospace Material Specifications (AMS). Produced as sand & permanent mold castings and available in two tempers, T4 and T7.

T6 is not selected due to concerns of stress corrosion cracking (SCC).

Contact us to collaborate on properties and casting design to meet your needs.

AMS 4236D Aluminum Alloy Casting, A206.0-T4

The T4 temper is lower strength yet higher elongation. Recommended for high toughness, high-fatigue, safety-critical applications that need to bend before breaking such as steering knuckles and control arms.

AMS 4235C Aluminum Alloy Casting, A206.0-T7

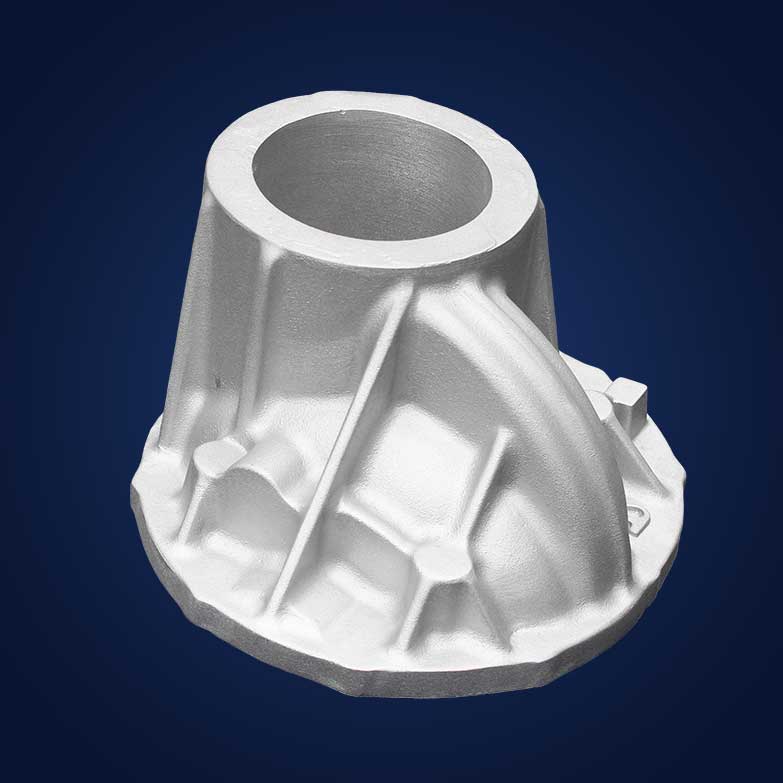

The T7 temper is higher strength yet lower elongation. Recommended for high strength, yet low impact applications like housings, wheel hubs.

Processes

Properties: Designated & Non-Designated Areas

| AMS 4236D A206-T4 Designated | Non-Designated | AMS 4235C A206-T7 Designated | Non-Designated | |

|---|---|---|---|---|

| Tensile Strength, min | 50 ksi (345 MPa) | 45 ksi (310 MPa) | 54 ksi (370 MPa) | 50 ksi (345 MPa) |

| Yield Strength at 0.2% Offset, min | 30 ksi (205 MPa) | 26 ksi (180 MPa) | 45 ksi (310 MPa) | 40 ksi (275 MPa) |

| Elongation in 2 inches or 4D, min | 10% | 8% | 3% | 1.5% |

| AMS 4236D A206-T4 Designated | Non-Designated | |

|---|---|---|

| Tensile Strength, min | 50 ksi (345 MPa) | 45 ksi (310 MPa) |

| Yield Strength at 0.2% Offset, min | 30 ksi (205 MPa) | 26 ksi (180 MPa) |

| Elongation in 2 inches or 4D, min | 10% | 8% |

| AMS 4235C A206-T7 Designated | Non-Designated | |

|---|---|---|

| Tensile Strength, min | 54 ksi (370 MPa) | 50 ksi (345 MPa) |

| Yield Strength at 0.2% Offset, min | 45 ksi (310 MPa) | 40 ksi (275 MPa) |

| Elongation in 2 inches or 4D, min | 3% | 1.5% |

Note: Premium properties available with close collaboration with foundry.

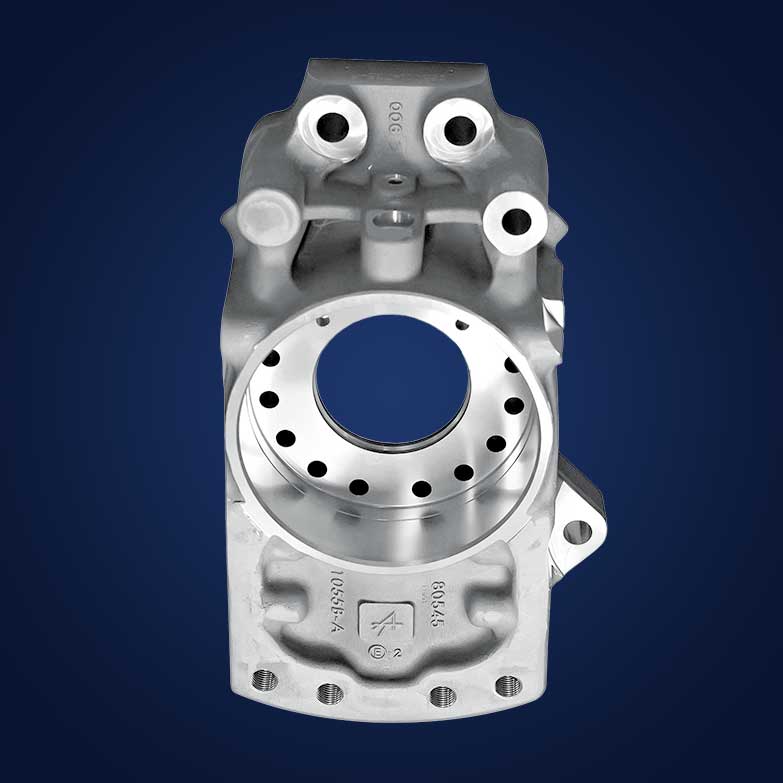

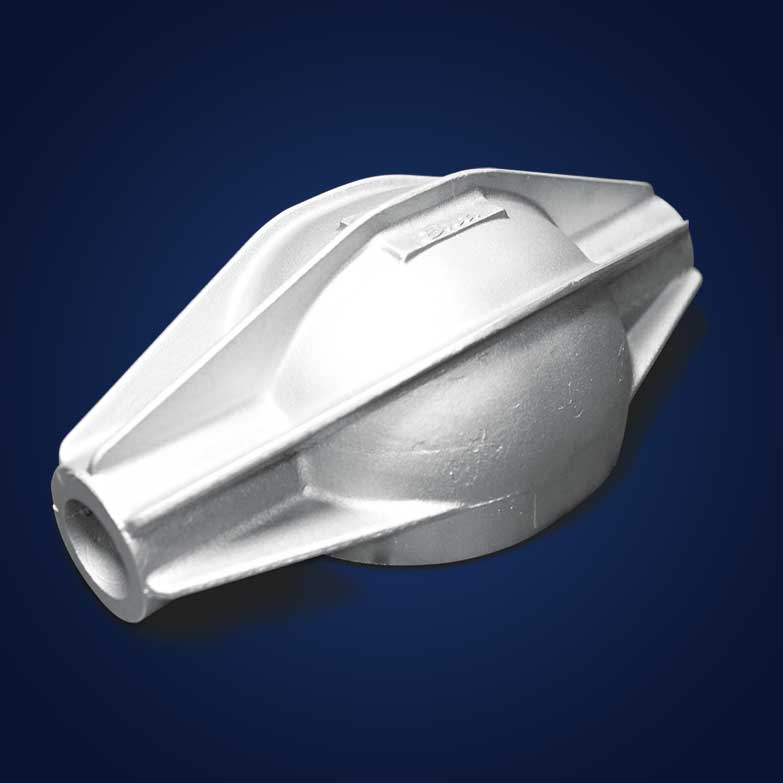

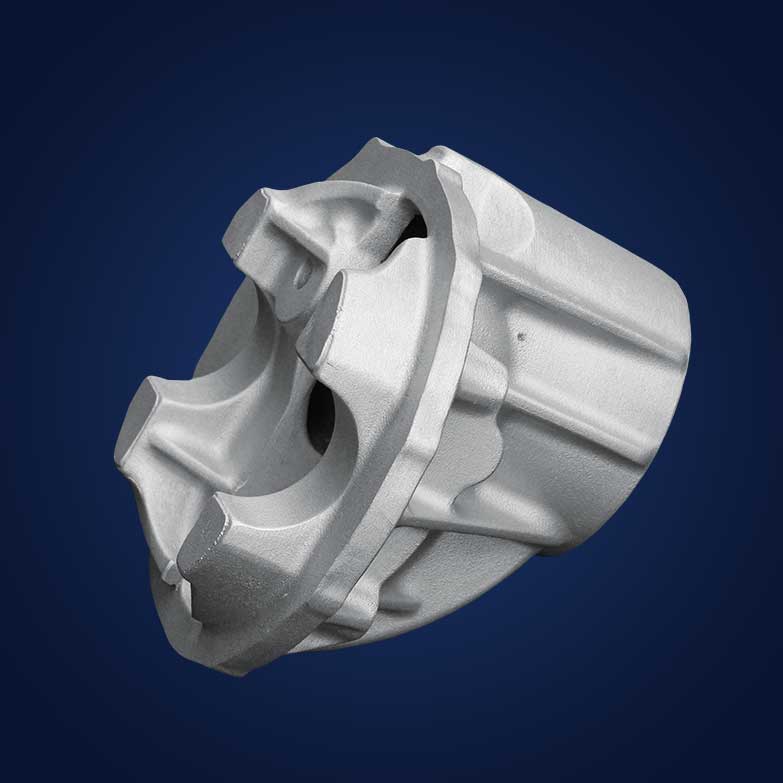

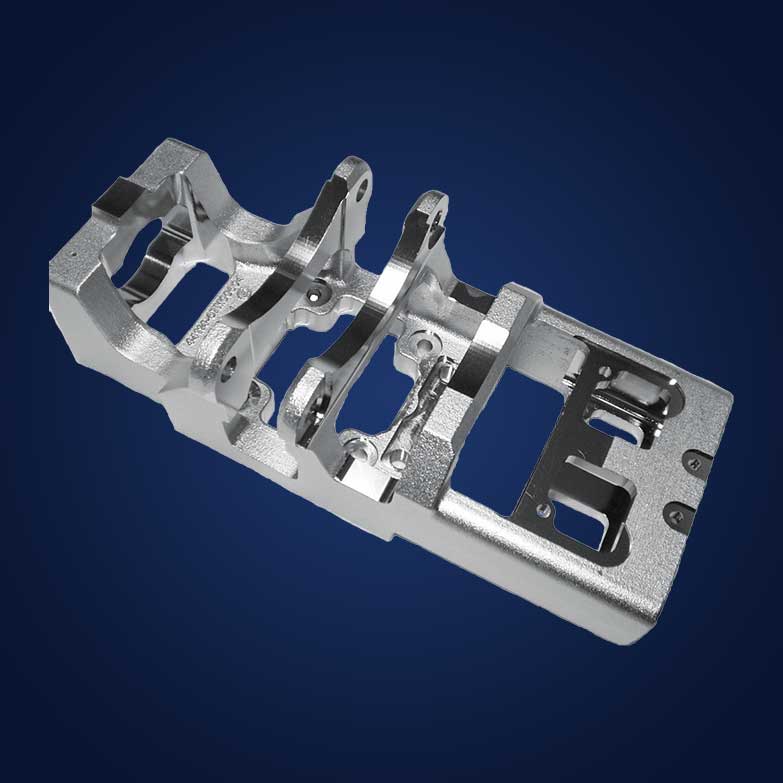

Applications

Lightweight Housings, Covers, Rear-Ends, Final Drives, Carriers, Brake Calipers, Steering Knuckles, Control Arms, Structures, RWS Gun Mounts

Let’s compare A206 to competing solutions:

A206 casting vs Ductile iron casting: 50% weight reduction

A206 casting vs A356 casting: Tougher, much improved fatigue

A206 casting vs Aluminum Forging: Similar properties, improved economics

Fatigue

A206-T4 has better high cycle fatigue strength than any aluminum alloy-temper combination. In multiple tests A206-T4 demonstrated runout of 100 million cycles at 15 KSI (103 MPa). It is 10X better than A356-T6.

Other properties

- Density: 0.101 lb/in3 (2.80 g/cc)

- CTE, 20-300C: 24.7 um/m C

- Thermal Conductivity: 121 W/m-K

- Shear Strength: 37.3 ksi (257 MPa) in T7 condition

- Hardness: Brinell Hardness 120, Rockwell 47

- Elastic Modulus: 10.2 Msi (70.3 GPa)

- Poisson’s Ratio: 0.33

- Fracture Toughness (K1C) of 206-T7: 39.2 ksi sqrt in

- Creep Strength: At 200-250C, creep strength of A206 is 40% better than A356 and A357, and alloys with Zr, V.

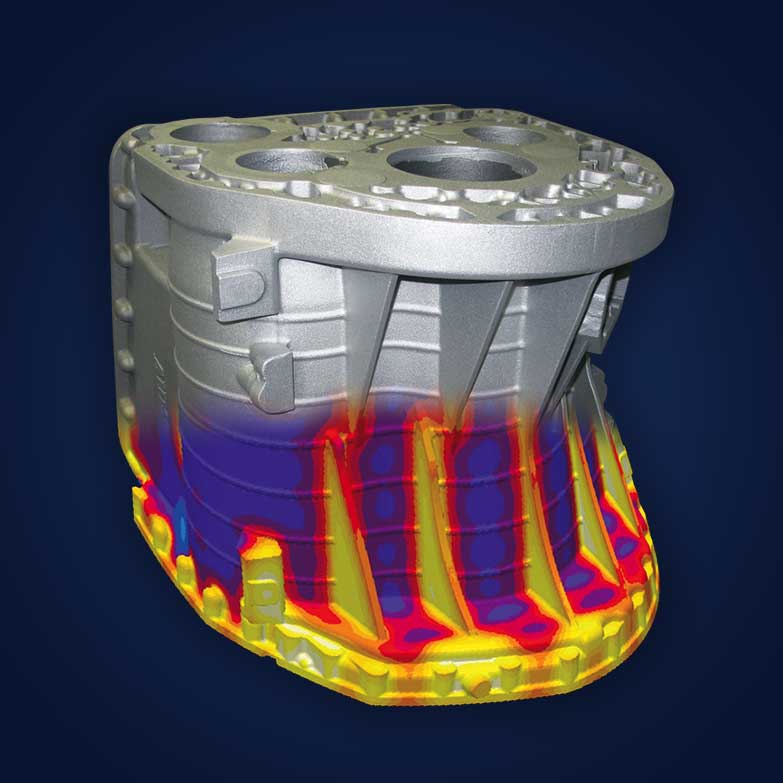

Modeling & Simulation

Eck Industries has been casting A206 for over 40 years; this experience, combined with solidification modeling that has been verified through extensive experimental correlations, positions us as a market leader in strong, cast aluminum alloys.

In addition, we collaborate with leading simulation software companies to develop simulation models specifically for A206.

Machining

Silicon is an abrasive particle, and the common A356 has 7% Si. A206 contains less than 0.1% silicon. It is easy to machine, and it cleans-up beautifully.

Corrosion Protection

A206 aluminum sand castings have been used by the US Army and Marine Corps since 1980 in applications exposed to sea water for decades without an issue.

Casting Processes

A206 aluminum castings have been produced for decades in sand castings and are now in production permanent mold. High performance with improved economics.