Innovation Never Rests

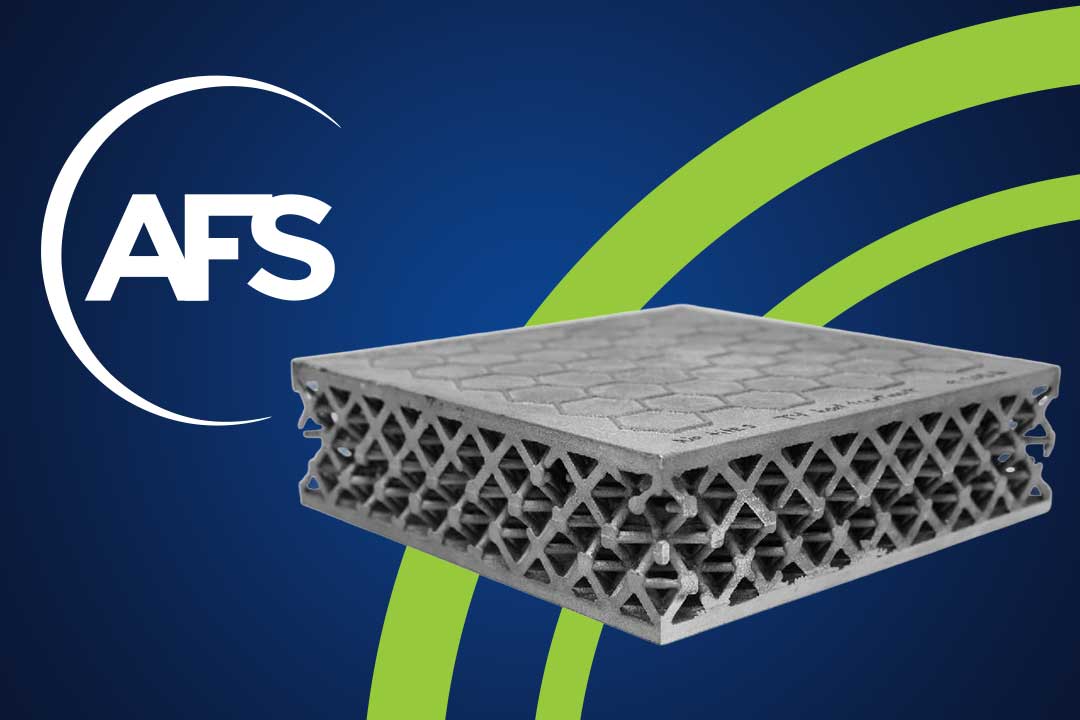

It is always an honor to be recognized by our peers in metal casting industry. This time, it is a shared award with the Virginia Tech Kroehling Advanced Materials Laboratory winning the Best Prototype or Innovation.

Clearly the lattice structure is a significant casting challenge, further complicated by an aluminum-copper alloy with nano reinforcement. The successful cast product delivered superior performance in an energy absorption application.

Metal-Ceramic Lattice Structure

Virginia Tech – Kroehling Advanced Materials Foundry (Blacksburg, Virginia) and Eck Industries (Manitowoc, Wisconsin)

- Material: A 206 alloy with 1% TiC nanoparticles.

- Process: Gravity-pour sand casting.

- Application: Military and commercial.

Cast metal-ceramic lattice structures were produced using 3D printed sand molds from a variety of metals and ceramic/hard metal tiles. The lattice structure properties were determined and then models were developed to optimize the structures and tailor them for specific applications.

In this research project, lattice structures were demonstrated to reduce the weight of a component (since the majority of the structure is open space) while maintaining as good or better penetration resistance and having superior penetration resistance compared to a solid piece of metal by combining an appropriate ceramic or hard metal tile within the lattice structure.

Published on: May 1, 2023