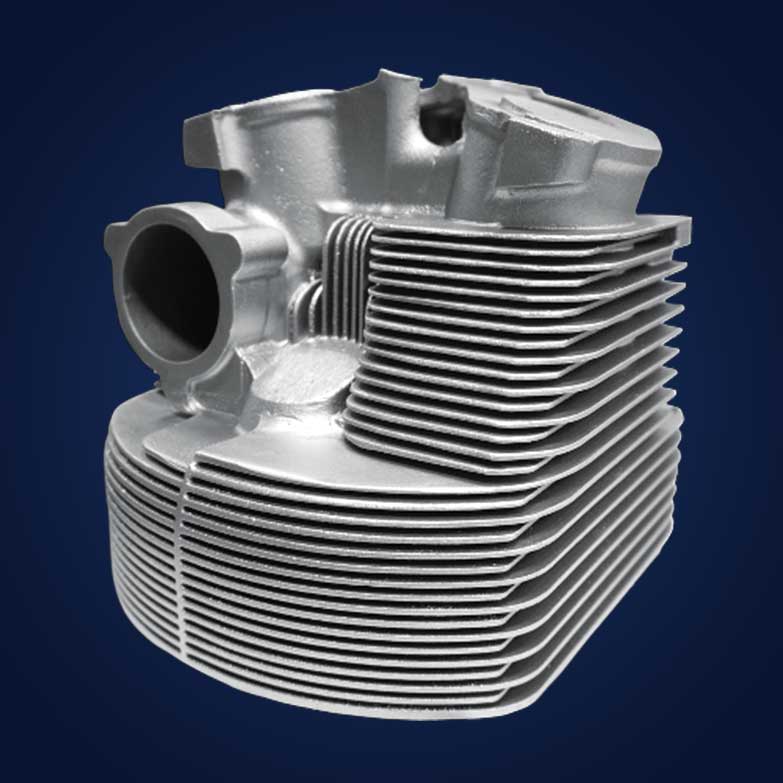

Eck Industries is a world-leading aluminum foundry in the 200 series alloys. A206 is well-suited for high toughness applications and 242 retains strength at elevated temperatures, making it a great choice for aircraft engines. We pour the most popular gravity cast alloy in the world, A356, and other alloys suited for specific applications.

Commonly Poured Alloys

| Alloy | Temper | Specification |

|---|---|---|

| A201 | T4 | AMS4223 |

| A201 | T7 | AMS4229 |

| 203 | T6 | AMS4225 |

| A206 | T4 | AMS4236 |

| A206 | T7 | AMS4235 |

| 224 | T7 | AMS4226 |

| A242 | T75 | AMS4220 |

| 319 | T5 | ASTM B26 |

| 355 | T6 | AMS4212 |

| 355 | T71 | AMS4214 |

| C355 | T6 | AMS4215 |

| A356 | T6 | AMS4218 |

| A357 | T6 | AMS4219 |

| D357 | T6 | AMS4241 |

| E357 | T6 | AMS4288 |

| F357 | T6 | AMS4289 |

| 535 | F | ASTM B26 |

| 850 | T5 | AMS4275 |

| 852 | T5 | ASTM B108 |

Heat Treatment

Heat treatment is processed in-house. We offer water and air quench and we can tailor our heat treat specifications to meet your mechanical property requirements. Most aluminum castings fit the T4, T5, T6 or T7 heat treatments.

Descriptions:

- F: As cast

- O: Annealed

- T4: Solution heat treated and naturally aged to a stable condition

- T5: Cooled from an elevated temperature shaping process and then artificially aged

- T6: Solution heat treated and then artificially aged

- T7: Solution heat treated and overaged

Heat Treat Definitions:

- Annealing: Heating castings to increase ductility, which also tends to decrease strength.

- Solution Heat Treat: Heating castings to a suitably elevated temperature and holding at that temperature long enough to allow elements to enter into a solid solution and then cooling rapidly to maintain that solid solution.

- Aging: Precipitation of solute atoms at room temperature (natural age) or elevated temperatures (artificial age).

- Overage: Additional aging to improve dimensional stability.